Carbon Fiber in Automotive Design: A Game-Changer for Performance and Weight Reduction

What is Carbon Fiber?

Carbon fiber is a high-performance material made from thin fibers of carbon atoms bonded together in a crystalline structure. It is typically used in composite materials, combining carbon fibers with a polymer matrix to form a lightweight yet extremely strong and rigid material. Carbon fiber’s high strength-to-weight ratio makes it ideal for applications in industries such as aerospace, sports equipment, and automotive manufacturing.

Benefits of Carbon Fiber in Automotive Design

- Enhanced Performance: The most significant advantage of carbon fiber is its ability to reduce vehicle weight. Lighter vehicles require less energy to accelerate, which improves fuel efficiency and driving performance.

- Improved Safety: Carbon fiber is incredibly strong and impact-resistant. In case of a collision, carbon fiber parts help absorb and dissipate the energy of the impact, improving vehicle safety.

- Corrosion Resistance: Unlike traditional metals, carbon fiber does not rust, making it ideal for external automotive components exposed to the elements.

- Customization and Design Flexibility: Carbon fiber’s unique properties allow for advanced design options. It can be molded into complex shapes, making it perfect for innovative car designs.

Applications of Carbon Fiber in Automotive Parts

Carbon fiber has many applications in automotive manufacturing. Below are some key areas where this material is utilized:

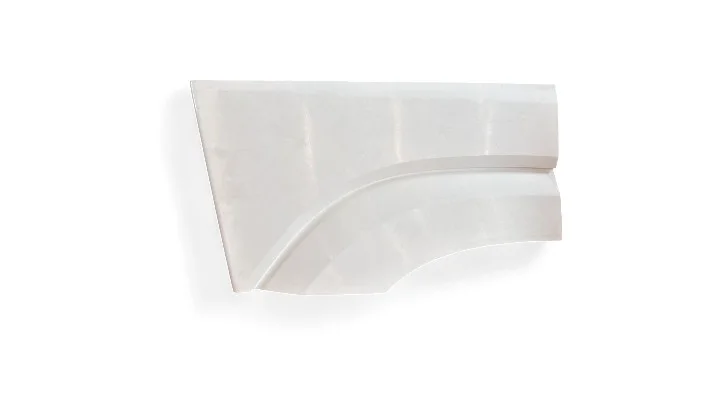

1. Carbon Fiber Automotive Exterior Components

One of the most popular applications of carbon fiber in automotive manufacturing is in automotive body panels, including housings, bumpers, roofs, and spoilers. These parts benefit from carbon fiber’s lightweight properties, which reduce the overall weight of the vehicle without sacrificing strength.

2. Automotive Carbon Fiber Parts for Interior Use

Carbon fiber is also used for various interior automotive components such as dashboard panels, door trims, and center consoles. These parts offer a premium look and feel while maintaining strength and rigidity.

3. Lightweight Carbon Fiber Car Parts for Performance Enhancement

Sports cars, racing cars, and electric vehicles benefit greatly from lightweight carbon fiber components such as brake rotors, drive shafts, wheels, and engine components. These parts contribute to faster acceleration, better fuel efficiency, and more responsive driving.

The Future of Carbon Fiber in Automotive Manufacturing

1. Cost Reduction and Mass Adoption

With ongoing advances in manufacturing technologies such as automated fiber placement (AFP) and resin transfer molding (RTM), carbon fiber production is becoming more cost-effective. This will lead to the mass adoption of carbon fiber in mainstream vehicles, not just high-performance models.

2. Sustainability and Recycling

As sustainability becomes a major focus in the automotive industry, carbon fiber presents a more eco-friendly option compared to traditional metals. Additionally, recycling carbon fiber is becoming more feasible, allowing for the reuse of materials in the production of new automotive parts.

3. Integration with Electric and Autonomous Vehicles

With the rise of electric vehicles (EVs) and autonomous vehicles, carbon fiber is set to play an even more significant role. EVs benefit from carbon fiber’s lightweight properties, which contribute to enhanced battery efficiency and longer driving range. Autonomous vehicles, with their need for precision engineering, also benefit from the strength and flexibility of carbon fiber in their design and construction.

Conclusion

Carbon fiber is a revolutionary material in the automotive industry, offering benefits that include reduced vehicle weight, improved performance, enhanced safety, and design flexibility. With its growing role in the production of automotive carbon fiber exterior components, lightweight carbon fiber car parts, and high-performance automotive components, carbon fiber is shaping the future of automotive design, particularly in the era of electric vehicles and sustainability.