Applications and Development Trends of Composites in Modular Construction

As the construction industry continues to trend toward lightweight, eco-friendly, rapid assembly, and customized development, composite building modules—as a next-generation building material solution—are gradually replacing traditional materials and becoming an essential component of modular construction. This article will systematically explain the application value, advantages, and industry prospects of composites in modular construction from multiple angles, including fa?ade materials, formwork composites, and modular building materials. It will also focus on the integration paths between modular building solutions and composite fa?ades and formwork, providing technical and material selection references for construction professionals. Sanse (cn-frp.net) specializes in composite solutions to help clients achieve high-quality construction goals.

1. The Rise of Composites in the Construction Industry

In recent years, demand for high-performance materials in construction has surged, especially in new building methods such as modular and prefabricated construction, which place higher demands on structural strength, light weight, durability, and customizability. Composite building materials, with their excellent mechanical properties, corrosion resistance, fire performance, and free-forming capability, have become the ideal choice to replace concrete, steel, and wood.

Common composites include fiberglass-reinforced plastic (FRP), carbon fiber-reinforced polymer (CFRP), SMC, BMC, etc., which can be manufactured into various modular building components through processes such as molding, pultrusion, and filament winding.

2. Fusion of Modular Construction and Composites

2.1 Advantages of Modular Construction

Modular construction refers to a method in which building components or units are prefabricated in a factory and then transported to the site for assembly. This approach offers shorter construction cycles, high precision, reduced pollution, and increased efficiency.

To achieve true modularity, standardization, and high performance, it is essential to select modular building materials that are lightweight, high-strength, and weather-resistant, which is exactly where composites excel.

2.2 Key Application Scenarios

- Composite building modules: Suitable for wall panels, roofs, floors, stairs, and other integral components, featuring light weight, waterproofing, and impact resistance.

- Modular building parts: Customizable components such as decorative panels, curtain wall panels, and railing systems; industrial production is enabled by composites’ moldability and pultrusion capability.

- Formwork composites: Lighter and more reusable than traditional wood or steel formwork, serving as critical auxiliary materials in construction.

3. Composite Fa?ade Solutions

Composite building fa?ades not only achieve architectural aesthetics but also provide durable, energy-saving, and fire-resistant exterior protection. They are commonly used in public buildings, high-end residences, and prefabricated fa?ade systems.

Advantages:

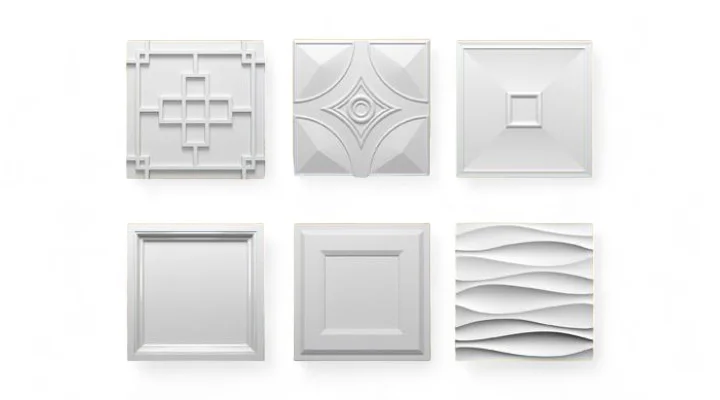

- Unlimited design shapes: Composites have excellent formability to meet complex geometric aesthetic requirements.

- Self-cleaning and stain resistance: Surfaces can be coated with fluorocarbon paint or nano self-cleaning materials to reduce maintenance costs.

- High fire rating: By adding flame retardants and multi-layer composite structures, A-class or B1 fire standards can be achieved.

- UV and weather resistance: Suitable for various climates, with a service life of over 20 years.

Typical Applications:

Exhibition halls, airport terminals, hospitals, commercial complexes, and new residential projects often adopt composite curtain wall systems with prefabricated panels. Some modular housing projects are also extensively integrating composite fa?ade materials to achieve energy savings, aesthetics, and sustainability.

4. Advantages of Composite Formwork Materials

Traditional wood formwork on construction sites has low reuse rates and is prone to moisture-induced deformation. Sanse recommends using fiberglass-reinforced composite formwork or SMC formwork to replace wood and steel formwork, delivering significant benefits:

- Lightweight and convenient, improving transport and installation efficiency

- Non-absorbent and corrosion-resistant, suitable for various site conditions

- Reusable 50–100 times, offering high cost-effectiveness

- Smooth demolding, enhancing concrete surface quality

5. Common Module-to-Composite Matching Table

| Application Scenario | Recommended Material | Technical Features |

|---|---|---|

| Wall Module | SMC/BMC | Fireproof, moisture-proof, high rigidity |

| Roof Module | FRP panels | Lightweight, weather-resistant, UV-resistant |

| Stair Tread | CFRP or pultruded profiles | High strength, anti-slip |

| Fa?ade Panel | GFRP composite panels | Custom shapes, diverse colors |

| Formwork | Fiberglass-plastic composite panels | High turnover, fast demolding |

6. Key Factors in Choosing a Quality Module Supplier

It is crucial to choose an experienced and strong modular building supplier:

- Owns in-house composite production and R&D capabilities

- Equipped with FRP/SMC/BMC molding and pultrusion equipment

- Supports modular building system design and custom matching

- Holds authoritative certifications for fire safety, strength, and environmental standards

- Provides integrated services from materials to module installation

As an industry-leading composite building module manufacturer, Sanse has provided efficient, eco-friendly, and customized module solutions for numerous construction projects.

7. Sustainability and Green Value of Composite Construction

Modular construction is driving the industry toward industrialized building, and the integration of composite formwork with composite fa?ades will further enhance the energy efficiency and green performance of building systems:

- Recyclable raw materials, eco-friendly and pollution-free

- Lightweight finished products, saving transport and hoisting costs

- Low maintenance costs and high energy efficiency throughout the lifecycle

- Can integrate solar panels, insulation layers, and smart sensing modules

Conclusion

With modular construction becoming more widespread and traditional materials unable to meet high standards and fast-paced demands, composite building modules, modular building parts, and composite formwork are emerging as key pathways for industry upgrades. Whether in composite fa?ade design or formwork systems, composites will play a starring role in the future. Partnering with a professional module supplier and staying on top of industry trends will bring lasting competitiveness to construction enterprises.

FAQs

Q1: Are composite materials for modular construction expensive?

Initial investment is slightly higher than traditional materials, but long-term value is greater, especially in construction speed, maintenance costs, and environmental performance.

Q2: Can composite fa?ades withstand cold or hot environments?

Yes, composites such as SMC and FRP can operate in temperatures from -40℃ to 120℃, offering excellent weather and thermal stability.

Q3: Does Sanse offer custom module development?

Sanse provides modular design consulting, 3D modeling, mold development, and mass production services suitable for various construction projects.