Comprehensive Solutions for High-Speed Train Composite Components: Leading Lightweight and High-Performance Manufacturing

As China’s high-speed railway industry continues to advance, there is an increasing demand for safety, energy efficiency, comfort, and aesthetics. To meet the dual requirements of lightweight and high strength, composite materials have become a preferred choice for both structural and functional components. Especially in high-speed train interior parts manufacturing, composite exterior components for high-speed trains, composite high-speed train car bodies, and various types of lightweight high-speed rail components, the application of composites is expanding and maturing rapidly.

1. Application Value of Composite Materials in High-Speed Train Interior Manufacturing

High-speed train interior parts must be visually appealing and comfortable while providing flame resistance, impact resistance, corrosion resistance, and being environmentally friendly and lightweight. Common components include seat shells, luggage racks, ceilings, wall panels, floors, and acoustic insulation modules.

SANSE (also known as cn-frp) adopts the following composite material solutions:

- SMC compression molding technology: Suitable for seat shells, hatches, and lamp covers, offering high strength, excellent flame resistance, and mass production capabilities.

- Honeycomb sandwich panels: Widely used in ceilings and side walls, providing lightweight and high rigidity performance.

- BMC materials: Ideal for small structural parts such as end caps, fastening blocks, and electrical enclosures.

- Carbon fiber composites: Used in specific areas to improve strength and reduce weight, preferred for premium train models.

The use of these composite materials not only reduces the overall weight of the train but also improves production efficiency and part consistency.

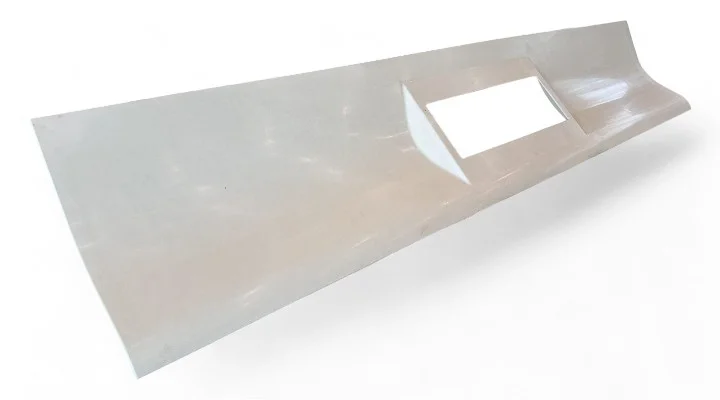

2. Composite High-Speed Train Exterior Parts: Enhancing Aerodynamics and Aesthetics

Exterior components play a critical role in determining aerodynamic performance and operating noise. Replacing traditional metals with composites allows for lightweight and integrated designs. Key exterior parts include train noses, skirts, side panels, underfloor ducts, and windshield trims.

Advantages of SANSE Composite Exterior Parts:

- Excellent UV resistance and weatherability, extending outdoor service life

- Composite forming processes support complex curves and aerodynamic shapes

- Large-size integrated molding reduces seams and installation complexity

- High design flexibility to accommodate various train models and speed classes

SANSE applies advanced technologies including SMC compression, RTM (Resin Transfer Molding), and automated carbon fiber lay-up to achieve high strength, low density, and superior stability.

3. Composite High-Speed Train Car Body: Building a Smart Lightweight Transport Platform

Modern high-speed trains are increasingly adopting composite car body structures to achieve weight reduction, insulation, noise control, and sustainability.

SANSE solutions include:

- Car body panels: Replacing metal with fiberglass or carbon fiber composite panels, reducing weight by over 30%

- Door systems: Molded composite panels with integrated flame resistance, impact resistance, and weather durability

- Modular ceiling and floor structures: Enabling rapid assembly and maintenance while enhancing structural stiffness

- Structural connectors: High-toughness resin-based composites that effectively absorb dynamic impacts

Integrating composites makes high-speed train car bodies lighter, more robust, and more energy-efficient, paving the way for “green high-speed railways.”

4. Lightweight High-Speed Train Parts: Combining Precision, Safety, and Durability

In auxiliary and functional systems of the train, SANSE provides customized solutions for lightweight high-speed rail components, including:

- Air ducts and HVAC enclosures: Made of FRP and SMC products to reduce energy use and noise

- Electrical boxes and housings: Offering excellent heat resistance and insulation

- Connecting structural parts: Lightweight yet featuring high creep strength and fatigue resistance

- Exterior trims and protective panels: Combining structural function and aesthetics, supporting customized colors and textures

Through optimized design and precision mold manufacturing, SANSE’s lightweight composite components are widely adopted in high-speed trains, meeting OEM demands for high reliability and long service life.

5. SANSE (cn-frp): Your Reliable Partner for Composite Railway Components

As a specialized composite material solution provider, SANSE offers a full-service system covering R&D, mold design, raw material formulation, compression molding, and assembly. We have long-term partnerships with domestic and international train manufacturers, providing comprehensive solutions for interior parts manufacturing, composite exterior parts, composite car bodies, and lightweight high-speed train parts.

SANSE features:

- Advanced hot compression mold development and multi-cavity tooling capabilities

- Automated SMC production lines, RTM infusion lines, and carbon fiber prepreg lay-up technology

- Composite materials meeting EN45545, TB/T3237 and other fire safety standards

- A professional engineering team to support custom development

Looking ahead, SANSE will continue to focus on the railway sector, advancing structural integration, intelligent functionality, and green manufacturing of high-performance composites — working together with industry partners to promote the sustainable development of high-speed rail.