Low Altitude Aircraft Interior and Exterior Components: Carbon Fiber Solutions

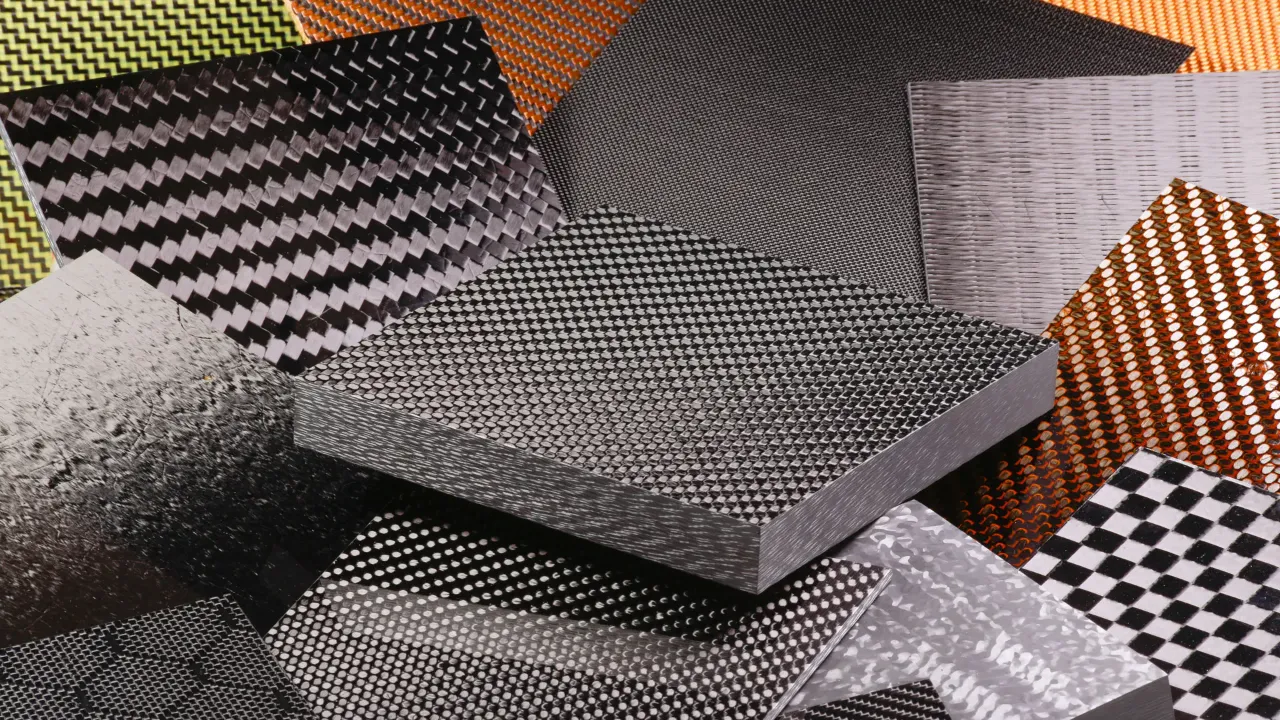

Low altitude aircraft demand high-performance materials to achieve lightweight, durability, and aerodynamics. Carbon fiber and composite materials have become key choices for manufacturing aircraft structural components, including fuselage shells, interior panels, and precision-molded parts.

1. Carbon Fiber Applications in Low Altitude Aircraft

Carbon fiber's high strength-to-weight ratio makes it ideal for aviation. Key applications include:

- Aircraft Fuselage: Carbon fiber-reinforced structures provide enhanced rigidity while reducing weight.

- Interior Components: Lightweight, fire-resistant, and aesthetically superior panels.

- Structural Parts: High-precision molded components ensuring aerodynamic efficiency.

2. Composite Materials for Aircraft Lightweight Solutions

Composite materials, including carbon fiber-reinforced polymers (CFRP), are widely used for:

- Weight Reduction: Significant fuel efficiency improvement.

- Corrosion Resistance: Longer lifespan compared to metal counterparts.

- Manufacturing Flexibility: Advanced molding techniques allow complex designs.

3. Molding Technologies for Aircraft Parts

Precision molding is crucial in the production of aircraft components. Methods include:

- Compression Molding: Used for high-strength carbon fiber panels.

- Resin Transfer Molding (RTM): Ideal for complex, lightweight structures.

- Autoclave Curing: Ensures superior material integrity.

4. Future Trends in Aircraft Composite Materials

The aviation industry continues to innovate in material science. Emerging trends include:

- Advanced Nanocomposites: Enhanced mechanical properties for next-generation aircraft.

- Eco-friendly Resins: Sustainable, bio-based polymers for greener aviation.

- Automation in Manufacturing: AI-driven production for increased efficiency.

5. Conclusion

The application of carbon fiber and composite materials in low altitude aircraft significantly improves performance, efficiency, and durability. As technology advances, these materials will play a crucial role in the future of aerospace engineering.