Application and Development of GMT Composite Materials in Automotive Exterior Parts and GMT Molded Components

1. Overview of GMT Composite Materials

GMT (Glass Mat Reinforced Thermoplastic) is a high-performance lightweight material, widely used in automotive exterior parts, GMT molded components, and high-strength structural parts. Compared to traditional metals and SMC (Sheet Molding Compound), GMT materials offer higher strength-to-weight ratios, impact resistance, and corrosion resistance, and meet the automotive industry's demand for environmentally friendly and recyclable materials.

2. Core Advantages of GMT Composite Materials

1. Lightweight, Reducing Overall Vehicle Energy Consumption

The density of GMT materials is only 1.0-1.2 g/cm3, significantly lower than traditional metal materials. This effectively reduces vehicle weight while maintaining high strength, improving fuel economy or the driving range of electric vehicles.

2. Excellent Mechanical Properties, Enhancing Safety

GMT materials have high rigidity and high impact resistance, which absorb impact force during a collision, thereby improving vehicle safety. They are widely used in GMT automotive components, such as seat frames, bumper brackets, etc.

3. Corrosion and Weather Resistance

GMT composite materials have far superior chemical corrosion resistance compared to metals and are not prone to rust. They can be used for long periods under different climatic conditions, suitable for automotive chassis protection plates, engine hoods, etc.

4. Recyclable, Environmentally Sustainable

Unlike traditional thermosetting materials (such as SMC), GMT is a thermoplastic material that can be recycled, reducing environmental pollution and aligning with green manufacturing trends.

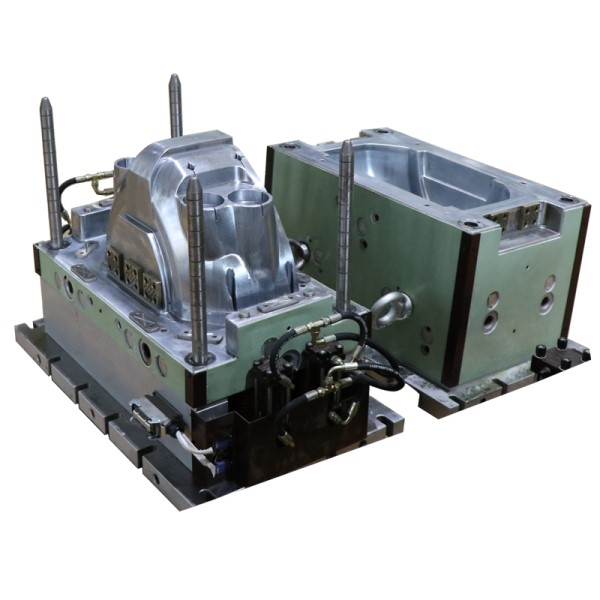

5. Efficient Molding Process, Reducing Production Costs

GMT uses molding technology, enabling the formation of complex structures in one step, improving production efficiency. This makes it suitable for mass production of GMT molded components.

3. Application of GMT Molded Components in the Automotive Field

- Exterior Body Parts: GMT is used in front and rear bumper brackets, inner door panels, engine hoods, etc., improving impact resistance.

- Body Structural Components: Such as seat frames, battery pack bottom protectors (for new energy vehicles), enhancing vehicle safety.

- High-Strength Components: Used in chassis protection plates, front-end modules, improving wear resistance.

4. Future Development Trends of GMT High-Strength Materials

1. Development of High-Performance GMT Materials

In the future, the development of carbon fiber reinforced GMT will enhance the strength and heat resistance of the material to meet higher performance requirements.

2. Intelligent Production Processes

Through intelligent temperature-controlled molds and automated production, the forming efficiency and quality stability of GMT components will be improved.

3. Green Recycling Development

The recycling process of GMT materials will be further optimized to achieve closed-loop recycling, promoting environmentally friendly development in the automotive industry.

5. Conclusion

With its advantages of lightweight, high strength, and recyclability, GMT composite materials are widely used in GMT automotive components, GMT molded parts. With the development of new energy vehicles and intelligent manufacturing, GMT materials will play an increasingly important role in the automotive industry.